Food & Beverage Processing

Food-grade, USP, and FCC-compliant chemicals for processing, CIP cleaning, pH adjustment, and preservation — with full lot traceability.

What Food & Beverage Processing Buyers Need

Food and beverage processors operate under strict regulatory scrutiny, primarily driven by the Food Safety Modernization Act (FSMA) and Global Food Safety Initiative (GFSI) schemes like SQF or BRC. Consequently, procurement teams prioritize supply chain visibility and material traceability above all else. When sourcing ingredients or processing aids, quality control managers require documentation that validates adherence to Food Chemicals Codex (FCC) or United States Pharmacopeia (USP) standards. Detailed Certificates of Analysis (COA) must accompany every lot to verify purity levels, heavy metal limits, and microbial profiles before a shipment is permitted to enter a facility.

Auditors frequently request evidence of a robust supplier verification program, making the availability of allergen statements, non-GMO certifications, and Kosher/Halal documentation essential for approval. Buyers also need assurance that manufacturing dates and shelf-life data align with production schedules to prevent inventory expiration. Consistency in physical properties, such as particle size for solids or precise concentration for liquid solutions like Phosphoric Acid, is critical for maintaining valid process parameters.

Auditors frequently request evidence of a robust supplier verification program, making the availability of allergen statements, non-GMO certifications, and Kosher/Halal documentation essential for approval. Buyers also need assurance that manufacturing dates and shelf-life data align with production schedules to prevent inventory expiration. Consistency in physical properties, such as particle size for solids or precise concentration for liquid solutions like Phosphoric Acid, is critical for maintaining valid process parameters.

Key Specifications

| Specification | Why It Matters |

|---|---|

| FCC/USP compliance | Regulatory requirement for food contact |

| Heavy metals (ppm) | FDA limits for food-grade chemicals |

| Microbial testing | Food safety verification |

| Kosher/Halal status | Market access for certified products |

| Lot traceability | Audit readiness and recall capability |

Recommended Products

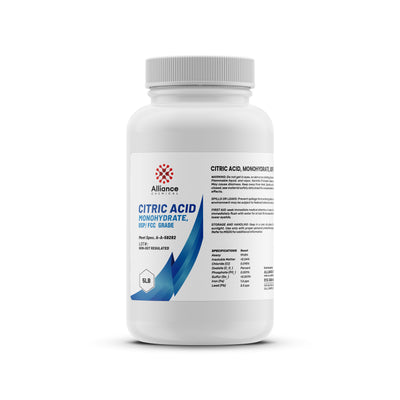

Citric Acid Monohydrate - USP Food Grade

pH adjustment, preservative, flavoring

From $13.98

View Product

Magnesium Chloride Hexahydrate FCC, USP GRADE

Tofu coagulant, mineral supplement

From $22.00

View ProductPackaging & Logistics

Chemical sourcing for food production requires packaging that maintains product integrity and prevents environmental contamination. High-volume processing plants typically utilize 275-gallon intermediate bulk containers (totes) or 55-gallon drums for liquid acidulants like Phosphoric Acid and Acetic Acid. These containers must use food-grade liners to ensure no interaction between the packaging material and the chemical. Powdered ingredients, such as Citric Acid Monohydrate or Potassium Bicarbonate, generally arrive in multi-ply paper bags with moisture barriers or super sacks for larger batching systems.

Logistics planning must account for hazardous material classifications, particularly for corrosive acids, which require specialized freight handling. Receiving departments also verify that tamper-evident seals are intact and that lot labeling is clearly visible on every package to facilitate immediate integration into inventory tracking systems.

Logistics planning must account for hazardous material classifications, particularly for corrosive acids, which require specialized freight handling. Receiving departments also verify that tamper-evident seals are intact and that lot labeling is clearly visible on every package to facilitate immediate integration into inventory tracking systems.

Common Mistakes to Avoid

A frequent oversight in chemical procurement involves confusing technical grade specifications with FCC or USP standards. While technical grade chemicals may appear chemically similar on a basic datasheet, they lack the rigorous heavy metal and impurity testing required for human consumption. Using non-food grade materials in a processing line violates FDA regulations and risks the safety status of the final product.

Buyers also occasionally overlook specific concentration requirements for Clean-in-Place (CIP) systems. For instance, substituting a 50% Citric Acid solution with a 25% concentration without adjusting process engineering calculations will result in ineffective descaling and potential microbial risks. Another pitfall involves neglecting the physical properties of ingredients like 85% Phosphoric Acid during colder months. Without temperature-controlled storage or heating capabilities at the receiving dock, high-concentration liquids can become viscous or verify, causing production delays while materials are conditioned for use.

Buyers also occasionally overlook specific concentration requirements for Clean-in-Place (CIP) systems. For instance, substituting a 50% Citric Acid solution with a 25% concentration without adjusting process engineering calculations will result in ineffective descaling and potential microbial risks. Another pitfall involves neglecting the physical properties of ingredients like 85% Phosphoric Acid during colder months. Without temperature-controlled storage or heating capabilities at the receiving dock, high-concentration liquids can become viscous or verify, causing production delays while materials are conditioned for use.

Why Alliance Chemical

COA Per Lot

Every lot ships with a Certificate of Analysis. Full traceability for your quality system.

SDS Included

Safety Data Sheets included with every order. Available on demand for any product.

Same-Day Shipping

Order by 2 PM CT and it ships today. DOT-certified hazmat packaging.

Real People

Call us and a person answers. No phone trees, no ticket queues. Taylor, Texas.

Made in the USAOwned and operated since 1998Certificate of Analysis (COA) available per lotSafety Data Sheet (SDS) provided with every orderTrusted by DOD, DLA, NASA, SOCOM, and Space ForceCAGE Code 1LT50Bulk pricing and purchase orders acceptedTechnical support availableContact: sales@alliancechemical.com

Frequently Asked Questions

How do you ensure lot traceability for FSMA compliance?

We maintain full traceability for every container shipped. Lot numbers are recorded on the container and the commercial invoice, allowing for rapid retrieval of origin data and Certificates of Analysis if an audit or recall occurs.

Are allergen statements or non-GMO documentation available?

Yes, specific statements regarding allergens, gluten content, and GMO status are available upon request for most food-grade products. These documents are designed to support your hazard analysis and supplier verification programs.

What is the difference between FCC and USP grades?

Both standards ensure high purity, but FCC (Food Chemicals Codex) specifically targets food ingredients, while USP (United States Pharmacopeia) covers pharmaceutical applications. Many products meet both standards, but buyers should confirm the specific designation required by their quality assurance team.

Do you provide Kosher or Halal certification for bulk chemical orders?

Current Kosher or Halal certificates are available for specific products upon request. We recommend verifying the certification status of the specific lot before purchase to ensure it meets your facility's religious dietary requirements.

Industry Insights & Guides

Deep-dive articles on the chemicals, processes, and best practices for Food & Beverage Processing.

The Essential Guide to Propylene Glycol in Food & Beverage Manufacturing

Introduction In today’s competitive food and beverage industry, manufacturers are constantly on the lookout for ingredients and processing...

Read Article →

Citric Acid: Beyond the Citrus Zest

While universally recognized for the tart flavor it imparts to citrus fruits, Citric Acid is one of the...

Read Article →

The Power of Phosphoric Acid: Industrial and Food-Grade Applications

Phosphoric acid is one of chemistry's most vital and versatile mineral acids. It's the hidden workhorse that treats...

Read Article →

Understanding Chemical Grades: Technical, ACS, USP, FCC, and Water Treatment Grades Explained

Understanding Chemical Grades: Technical, ACS, USP, FCC, and Water Treatment Grades Explained In the vast world of...

Read Article →

Why Beef Processors Use d-Limonene: Odor, Grease, and Uptime

The 2 a.m. lift station failure is a plant manager's worst nightmare. In our definitive guide, we break...

Read Article →

How to Descale an Espresso Machine with Food‑Grade Citric Acid—Exact Ratios & Safety Tips

Discover how to use food-grade citric acid to effectively descale your espresso machine at a fraction of the...

Read Article →Ready to Order?

Get the chemicals your Food & Beverage Processing operation needs — with documentation, fast shipping, and real support.

Or call: (512) 894-2194

Unit price

Compare Products

| Price |

|---|

| SKU |

| Rating |

| Discount |

| Vendor |

| Tags |

| Weight |

| Stock |

| Short Description |