-

Industries

- Semiconductor Manufacturing

- Data Center Cooling

- Water & Wastewater Treatment

- Metal Finishing & Surface Treatment

- Laboratory & Pharma Research

- Cannabis, Kratom & Botanical Extraction

- Paper & Pulp

- Craft Distilling & Spirits

- Oil & Gas

- Government & Municipal

- Food & Beverage Processing

- HVAC & Geothermal

- Cosmetics & Personal Care

- Aerospace & Defense

Ask a question

Product Overview

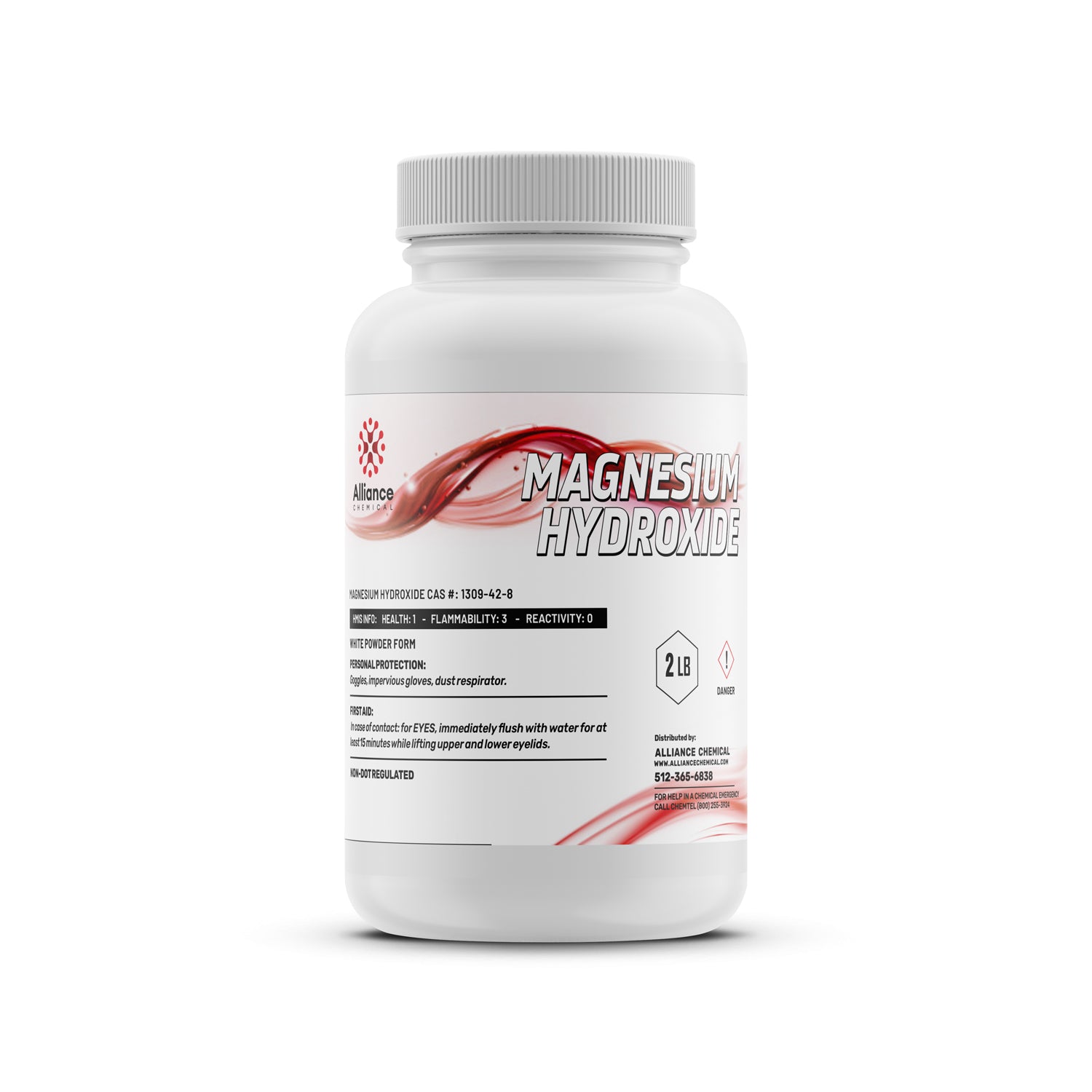

Magnesium Hydroxide Technical (Mg(OH)₂) is a white solid powder widely specified for industrial chemical processing and environmental management. With a typical assay of 97.5%, this high-purity technical grade material offers consistent performance in neutralization, buffering, and acid-scavenging applications. It serves as a safer, more controlled alternative to stronger alkalis like caustic soda, providing a buffering effect that prevents pH overshoot.

In industrial operations, Magnesium Hydroxide acts as a primary neutralizing agent for acidic wastewater and flue gas desulfurization. Its low solubility allows for the gradual release of hydroxide ions, maintaining stable pH levels in biological treatment systems. The material exhibits a density of approximately 2.36 g/mL at 25°C and rigorous impurity controls for chlorides and heavy metals, making it suitable for sensitive formulation strategies in plastics, flame retardants, and composite materials.

Key Properties

- Chemical Formula: Mg(OH)₂

- Grade: Technical

- Assay (wt%): 95.0% - 100.0% (Typical 97.5%)

- Appearance: White powder

- Specific Gravity: 2.34 - 2.40 (Typical 2.38)

- Solubility: Slightly soluble in water

- Chloride (ppm): Max 1000

- Heavy Metals (as Pb): Max 0.5 ppm

Common Applications

- Wastewater Treatment: Used to adjust pH levels in effluent streams, providing controlled neutralization and precipitation of heavy metals without the risk of drastic pH spikes.

- Flue Gas Desulfurization: Captures sulfur dioxide (SO₂) in scrubbing systems to reduce industrial emissions.

- Flame Retardant: Incorporated into construction materials and plastics to enhance fire resistance through endothermic decomposition and char formation.

- Plastic Filler: utilized in polymer formulations to improve mechanical properties, dimensional stability, and processing behavior.

- Chemical Manufacturing: Acts as a raw material and neutralizing agent in chemical synthesis and catalyst production.

Safety Precautions

Handle Magnesium Hydroxide Technical with appropriate Personal Protective Equipment (PPE), including chemical-resistant gloves, safety goggles, and protective clothing to prevent dust irritation. Store in a cool, dry, well-ventilated area away from incompatible materials such as strong acids and oxidizing agents. Keep containers tightly closed to prevent moisture absorption.

First Aid: In case of eye contact, rinse cautiously with water for several minutes. For skin contact, wash thoroughly with soap and water. If inhaled, move to fresh air. Refer to the Safety Data Sheet (SDS) for comprehensive handling and emergency procedures.

Benefits

Effective Neutralization – Provides high alkalinity per unit weight with a self-buffering mechanism that improves process safety.

High Purity Profile – Low trace metal content ensures compatibility with sensitive chemical formulations and environmental regulations.

Versatile Utility – Functions effectively as both a chemical reactant and a functional filler in material science applications.

Related Products

| Property | Value |

|---|---|

| Molecular Weight | 58.32 g/mol |

| Formula | Mg(OH)2 |

| Grade | Technical |

| Flash Point | N/A |

| Form | Solid |

| Solubility | Slightly soluble in water, insoluble in alcohol |

| Appearance | White, odorless powder |

| Melting Point | 350 °C |

| Boiling Point | 354 °C |

| Specific Gravity | 2.36 |

| Industry | Industrial, Environmental |

Frequently Asked Questions About Magnesium Hydroxide Technical

What is Magnesium Hydroxide Technical and what is its chemical formula?

Magnesium Hydroxide Technical is a chemical compound with the molecular formula Mg(OH)2, registered under CAS Number 1309-42-8 by the Chemical Abstracts Service (PubChem), with a molecular weight of 58.32 g/mol. Alliance Chemical supplies Magnesium Hydroxide Technical in Technical grade for laboratory, industrial, and commercial applications.

What are the physical properties of Magnesium Hydroxide Technical?

According to the NIOSH Pocket Guide to Chemical Hazards, Magnesium Hydroxide Technical is supplied as a solid with a white, odorless powder appearance. It has a melting point of 350°C, a boiling point of 354°C, a flash point of N/A. The specific gravity is 2.36 relative to water. Solubility: Slightly soluble in water, insoluble in alcohol.

What grade and purity of Magnesium Hydroxide Technical does Alliance Chemical offer?

Alliance Chemical offers Magnesium Hydroxide Technical in Technical grade. Every lot ships with a Certificate of Analysis (COA) and Safety Data Sheet (SDS) prepared in accordance with OSHA Hazard Communication Standard 29 CFR 1910.1200 and GHS Revision 7. Download SDS.

What are common industrial applications of Magnesium Hydroxide Technical?

Magnesium Hydroxide Technical serves a wide range of sectors, including Industrial, and Environmental.Alliance Chemical provides the documentation and quality certifications required for use in regulated environments.

What PPE is required when handling Magnesium Hydroxide Technical?

OSHA-mandated PPE per 29 CFR 1910.132-138:Chemical-resistant gloves (20+ mil neoprene or PVC), full face shield over safety goggles (ANSI Z87.1), acid-resistant apron or chemical suit, closed-toe chemical-resistant footwear. Respiratory protection (organic vapor cartridge) required in areas exceeding PEL/TLV per 29 CFR 1910.134. Emergency eyewash station and safety shower must be accessible within 10 seconds per ANSI Z358.1. Consult the SDS available from Alliance Chemical for complete PPE requirements.

What are the storage requirements for Magnesium Hydroxide Technical?

Store perOSHA 29 CFR 1910.106: Approved flammable storage cabinet, maximum 60 gallons per cabinet, grounding/bonding required. Temperature range:15-25°C. Segregate from:acids, aluminum, zinc. Maximum storage:2-3 years unopened.

What is the emergency spill procedure for Magnesium Hydroxide Technical?

Emergency response per EPA SPCC (40 CFR 112) and OSHA 29 CFR 1910.120: (1) Alert personnel, evacuate area to 100 feet. (2) Eliminate ignition sources if flammable. (3) Don PPE per SDS Section 8. (4) Stop leak if safe; use emergency shutoffs. (5) Contain with non-combustible absorbent materials, dike with sand/earth. (6)Neutralize with citric acid or acetic acid (5% solution). (7) Collect in DOT-approved containers, label as hazardous waste. Check 40 CFR 302.4 for Reportable Quantity. Emergency: Chemtel 1-800-255-3924 (24/7). Non-emergency: Alliance Chemical 512-365-6838.

What is the DOT shipping classification for Magnesium Hydroxide Technical?

DOT Classification per 49 CFR 172.101:See SDS Section 14 for specific UN number, Hazard Class8 (Corrosive), Packing GroupII/III. Requires: Hazmat shipping papers (49 CFR 172.200), UN specification packaging (49 CFR 173), hazmat labels (172.400). Alliance Chemical ships all orders in DOT-compliant packaging with proper documentation.

How must Magnesium Hydroxide Technical waste be disposed?

Disposal per RCRA (40 CFR 261-265):Characteristic waste D002 (Corrosive, pH ≤2 or ≥12.5). Generator requirements: EPA ID number required if >100 kg/month (40 CFR 262.12). Use EPA-permitted Treatment, Storage, Disposal Facility (TSDF). Never discharge to sewer without POTW written approval (40 CFR 403). Container disposal: Triple rinse (40 CFR 261.7), offer for reconditioning/recycling. State regulations may be more stringent — check with your local environmental agency. Consult the Alliance Chemical SDS for product-specific disposal guidance.

Does Alliance Chemical provide an SDS and COA for Magnesium Hydroxide Technical?

Yes. Alliance Chemical provides a Safety Data Sheet (SDS) and Certificate of Analysis (COA) for every lot of Magnesium Hydroxide Technical. The SDS is prepared in accordance with OSHA Hazard Communication Standard 29 CFR 1910.1200 and the Globally Harmonized System (GHS) Revision 7, covering all 16 required sections including hazard identification, first aid measures, firefighting measures, handling and storage, exposure controls, and regulatory information. The SDS is available for download directly from this product page. COAs are available upon request by contacting Alliance Chemical at 512-365-6838.

LVL-CPP-MCT

$18.00

Unit price

Compare Products

| Price |

|---|

| SKU |

| Rating |

| Discount |

| Vendor |

| Tags |

| Weight |

| Stock |

| Short Description |