Email sales@AllianceChemical.com for 24/7 Expert Support

-

512-365-6838

-

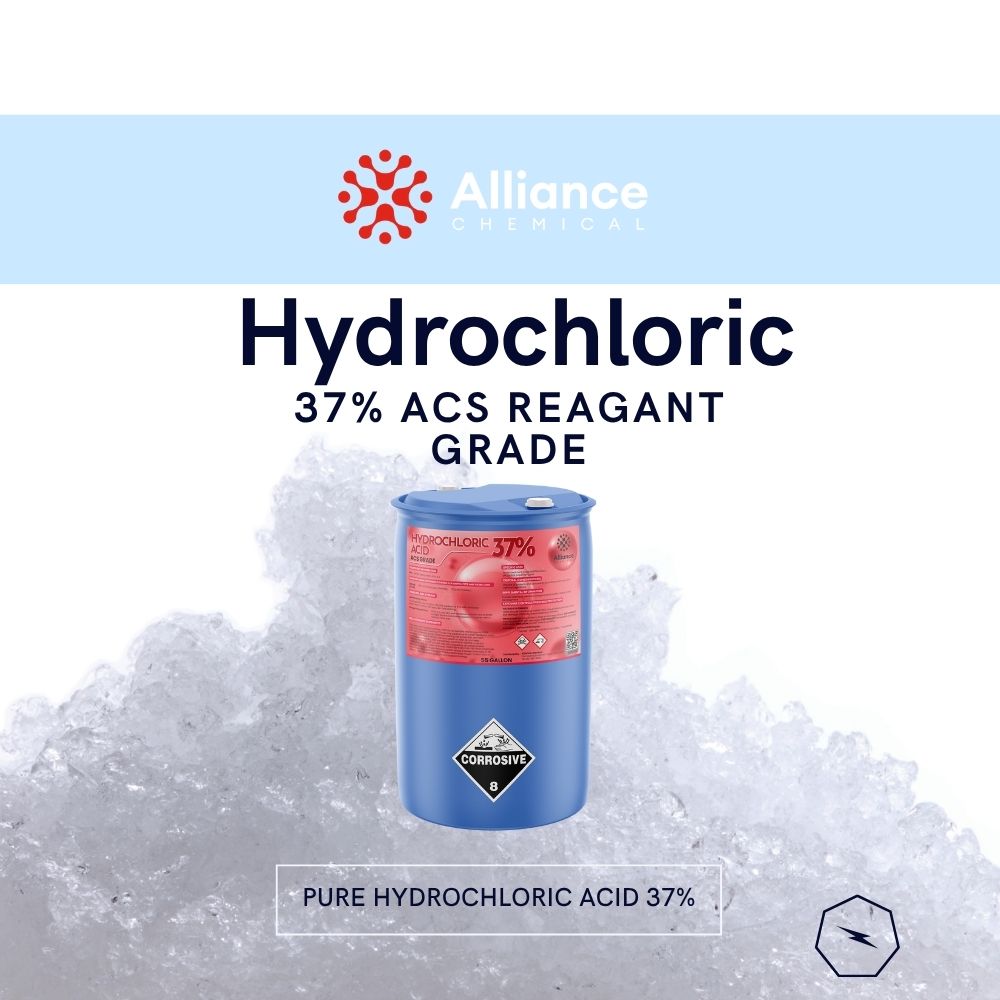

Hydrochloric Acid 37% ACS Reagent Grade

Category : Acids

$29.50

$0.00

Liquid error (snippets/product-blocks line 100): divided by 0

Off

Unit price

/

Shipping Notice: Possible Hazmat Fees

💡 Smart Shipping Tip: Quart & Liter Sizes Often Avoid Hazmat Fees

This size may be classified as hazmat and can incur additional carrier fees. See shipping guide

- ✅ Good news: 1 Quart containers qualify as "Limited Quantity" and bypass hazmat rules

- 💡 Pro tip: Order multiple 1 Quart containers to avoid hazmat fees entirely

- 💰 Hazmat fees can get expensive - especially for larger containers (carrier charges, not our markup)

- 🚚 Ground shipping only - no expedited options for sizes over 1 Qt/1L

Required by 49 CFR § 173.150 for chemical containers larger than 1 quart. Actual fees shown at checkout. View our complete shipping guide →

✅ Great Choice! No Hazmat Fees

1 Quart containers qualify as "Limited Quantity" and avoid hazmat shipping fees.

- 🚀 Faster shipping: Eligible for expedited shipping options including air transport

- 💰 No hazmat fees: Ships as "Limited Quantity" per DOT regulations

- 📦 Convenient size: Perfect for testing or smaller applications

- ♻️ Smart choice: Order multiple quarts to get the volume you need without hazmat charges

Exempted under 49 CFR § 173.150 Limited Quantity provisions for containers ≤1 liter/quart. Learn more in our shipping guide →

Quantity

Size:

Variation:

-

$29.50Delivery every$28.03

-

$49.00Delivery every$46.55

-

$95.00Delivery every$90.25

-

$145.00Delivery every$137.75

-

$88.00Delivery every$83.60

-

$150.00Delivery every$142.50

-

$290.00Delivery every$275.50

-

$9,500.00Delivery every$9,025.00

-

$340.00Delivery every$323.00

-

$1,300.00Delivery every$1,235.00

-

$8,640.64Delivery every$8,208.61

-

$950.00Delivery every$902.50

-

$1,750.00Delivery every$1,662.50

-

$6,900.00Delivery every$6,555.00

-

$8,600.00Delivery every$8,170.00

-

$9,804.00Delivery every$9,313.80

$29.50

$0.00

Liquid error (snippets/product-sticky-blocks line 69): divided by 0

Off

Unit price

/

Hydrochloric Acid 37% ACS Reagent Grade

$29.50

$0.00

Liquid error (snippets/sticky-product line 56): divided by 0

Off

Unit price

/

Size:

Variation:

-

$29.50Delivery every$28.03

-

$49.00Delivery every$46.55

-

$95.00Delivery every$90.25

-

$145.00Delivery every$137.75

-

$88.00Delivery every$83.60

-

$150.00Delivery every$142.50

-

$290.00Delivery every$275.50

-

$9,500.00Delivery every$9,025.00

-

$340.00Delivery every$323.00

-

$1,300.00Delivery every$1,235.00

-

$8,640.64Delivery every$8,208.61

-

$950.00Delivery every$902.50

-

$1,750.00Delivery every$1,662.50

-

$6,900.00Delivery every$6,555.00

-

$8,600.00Delivery every$8,170.00

-

$9,804.00Delivery every$9,313.80

Ask a question

- Description

- Product Documents

Product Overview

Hydrochloric Acid 37% ACS Reagent Grade is a high-purity, inorganic mineral acid formulated for analytical and laboratory applications where stringent purity is critical. Also known as high-grade Muriatic Acid, Hydrogen Chloride solution, or Spirits of Salt, this 37% w/w HCl solution provides a strongly acidic medium suitable for pH adjustment, sample digestion, and chemical synthesis.

Prepared to meet the rigorous standards of Reagent Chemicals (11th Edition) and USP-NF Monograph requirements, this product features controlled trace metal content and low residue after evaporation. It ensures reproducible results in sensitive procedures. The clear to pale yellow liquid has a density of approximately 1.19 g/mL at 25°C. A lot-specific Certificate of Analysis (COA) is available to validate performance parameters, including assay accuracy and impurity profiles, supporting compliance in regulated industrial and laboratory environments.

Key Properties

- Appearance: Colorless to pale yellow liquid

- Chemical Formula: HCl

- Molecular Weight: 36.46 g/mol

- Boiling Point: 100°C (azeotrope with water)

- Specific Gravity (20°C): 1.19 (range 1.18 – 1.20)

- Residue After Ignition: Max 0.01% (typical 0.005%)

- Chloride (Cl): Max 3,000 ppm (typical 1,500 ppm)

- Nitrate (NO3⁻): Max 5 ppm (typical 2 ppm)

- Heavy Metals (as Pb): Max 0.1 ppm (typical 0.02 ppm)

- Iron (Fe): Max 0.2 ppm (typical 0.05 ppm)

- Available Chlorine (Cl₂): 99–100% (typical 99.6%)

Common Applications

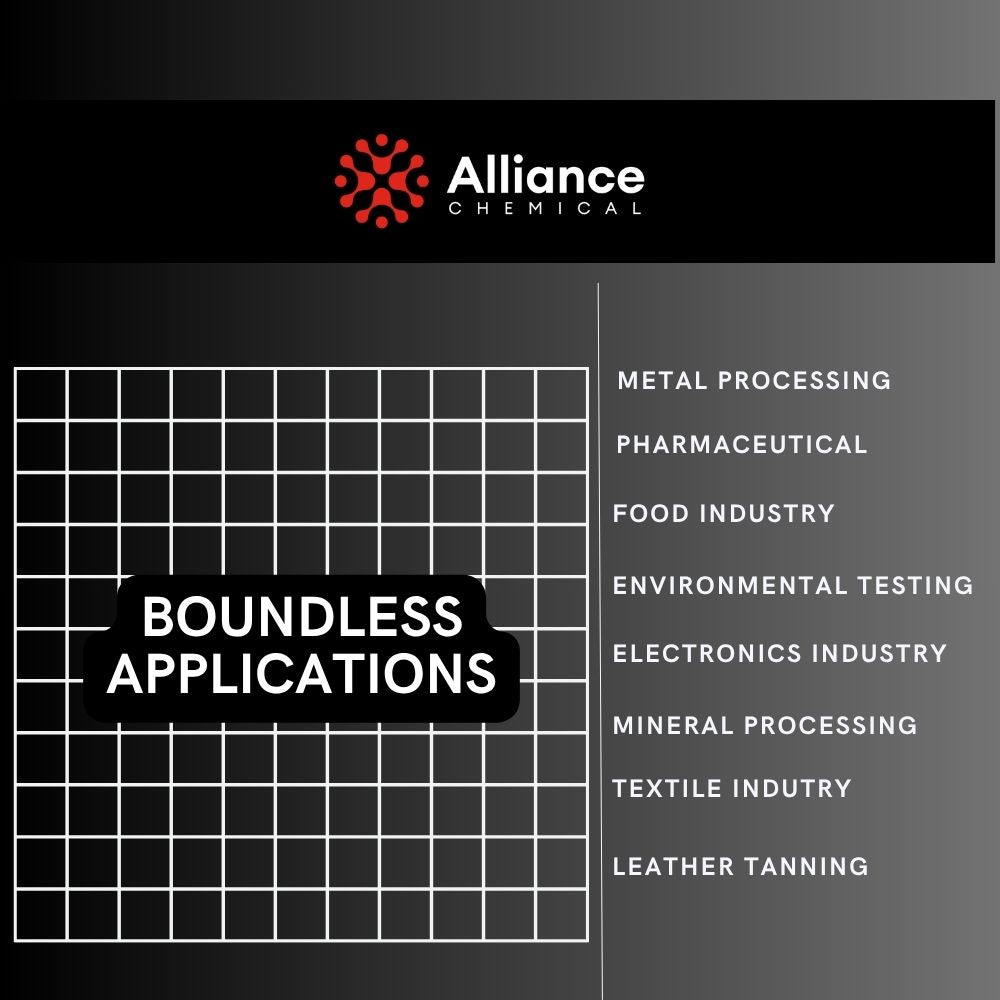

- Laboratory Reagent: Utilized for standard calibration, sample digestion, and analytical titrations in high-purity chemistry labs ensuring traceable results.

- pH Adjustment: Industrial water treatment and laboratory workflows use this grade for precise acidification and process control where minimizing contaminants is essential.

- Chemical Synthesis: Serves as a primary reagent in synthesis pathways requiring strong acidity and chloride sources with controlled impurity profiles.

- Metal Processing: Employed for oxide and scale removal in specialized metal finishing and surface preparation applications.

- Catalyst Preparation: Acts as a reactive acid component in catalytic cycles and acid-activated surface treatments within chemical manufacturing.

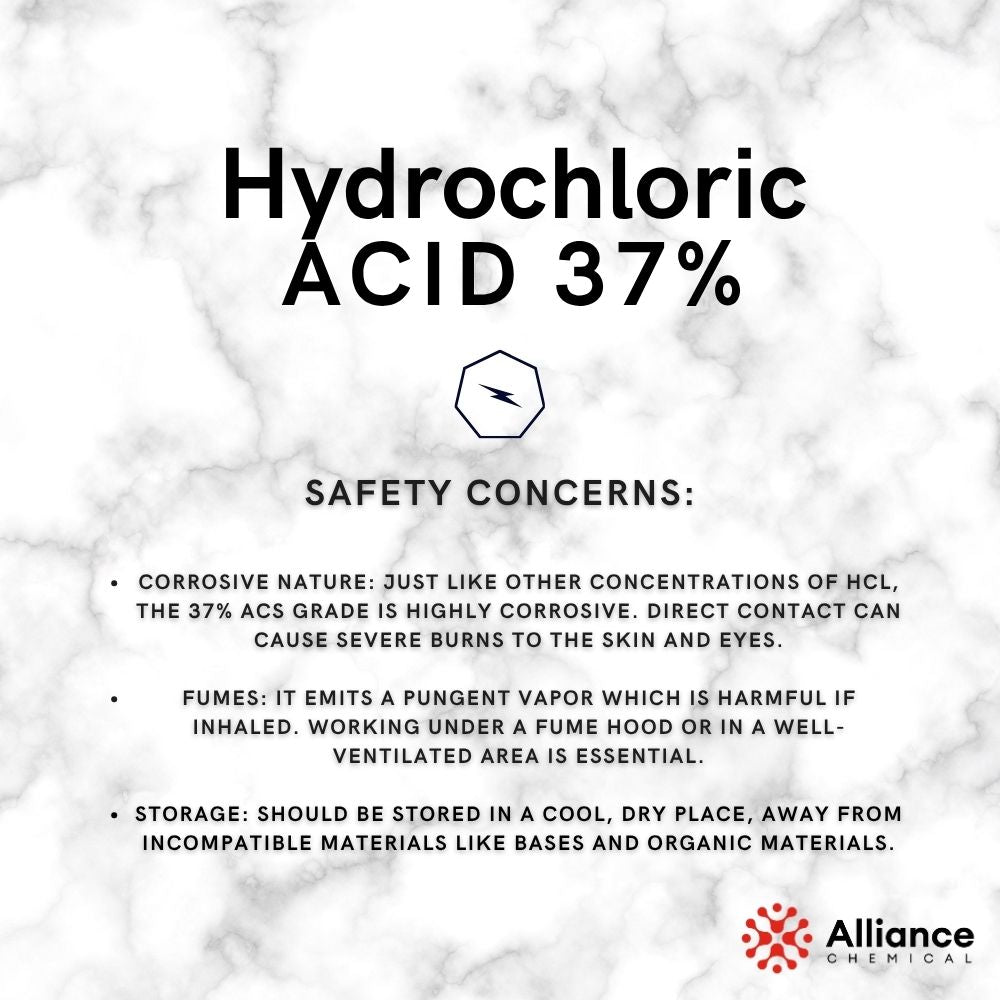

Safety Precautions

Hydrochloric Acid is corrosive. Handle under a chemical-compatible fume hood with appropriate PPE, including chemical-resistant gloves, splash goggles, face shield, and acid-resistant apron. Store in corrosion-resistant containers (HDPE or glass) away from metals, bases, and organics. Keep containers tightly closed to prevent moisture uptake and vapor release.

In case of exposure, refer to the SDS: flush eyes or skin with water immediately; move to fresh air if inhaled. Transported as UN 1789, Hydrochloric Acid, Class 8, PG II.

Benefits

High-Purity ACS Grade: Meets ACS Reagent Grade specifications for reliable analytical performance in regulated environments.

Low Impurity Profile: Optimized trace metal levels minimize interference in analytical measurements.

Trusted Quality: Manufactured to ensure consistency across batches for industrial and research reliability.

Related Products

| Property | Value |

|---|---|

| Molecular Weight | 36.46 g/mol |

| Formula | HCl |

| Assay | 37% |

| Flash Point | Does not apply |

| Form | Liquid |

| Solubility | Fully miscible with water, most organic solvents |

| Appearance | Clear, colorless corrosive liquid |

| Melting Point | -114 °C |

| Boiling Point | 108 °C |

| Industry | Research, Chemical Manufacturing, Materials Testing, Industrial Processing |

Other top rated products

9QB-Y99-XMR

$29.50

$0.00

Liquid error (snippets/product-blocks line 100): divided by 0

Off

Unit price

/

Shipping Notice: Possible Hazmat Fees

💡 Smart Shipping Tip: Quart & Liter Sizes Often Avoid Hazmat Fees

This size may be classified as hazmat and can incur additional carrier fees. See shipping guide

- ✅ Good news: 1 Quart containers qualify as "Limited Quantity" and bypass hazmat rules

- 💡 Pro tip: Order multiple 1 Quart containers to avoid hazmat fees entirely

- 💰 Hazmat fees can get expensive - especially for larger containers (carrier charges, not our markup)

- 🚚 Ground shipping only - no expedited options for sizes over 1 Qt/1L

Required by 49 CFR § 173.150 for chemical containers larger than 1 quart. Actual fees shown at checkout. View our complete shipping guide →

✅ Great Choice! No Hazmat Fees

1 Quart containers qualify as "Limited Quantity" and avoid hazmat shipping fees.

- 🚀 Faster shipping: Eligible for expedited shipping options including air transport

- 💰 No hazmat fees: Ships as "Limited Quantity" per DOT regulations

- 📦 Convenient size: Perfect for testing or smaller applications

- ♻️ Smart choice: Order multiple quarts to get the volume you need without hazmat charges

Exempted under 49 CFR § 173.150 Limited Quantity provisions for containers ≤1 liter/quart. Learn more in our shipping guide →

Size:

Variation:

-

$29.50Delivery every$28.03

-

$49.00Delivery every$46.55

-

$95.00Delivery every$90.25

-

$145.00Delivery every$137.75

-

$88.00Delivery every$83.60

-

$150.00Delivery every$142.50

-

$290.00Delivery every$275.50

-

$9,500.00Delivery every$9,025.00

-

$340.00Delivery every$323.00

-

$1,300.00Delivery every$1,235.00

-

$8,640.64Delivery every$8,208.61

-

$950.00Delivery every$902.50

-

$1,750.00Delivery every$1,662.50

-

$6,900.00Delivery every$6,555.00

-

$8,600.00Delivery every$8,170.00

-

$9,804.00Delivery every$9,313.80

Compare Products

| Price |

|---|

| SKU |

| Rating |

| Discount |

| Vendor |

| Tags |

| Weight |

| Stock |

| Short Description |