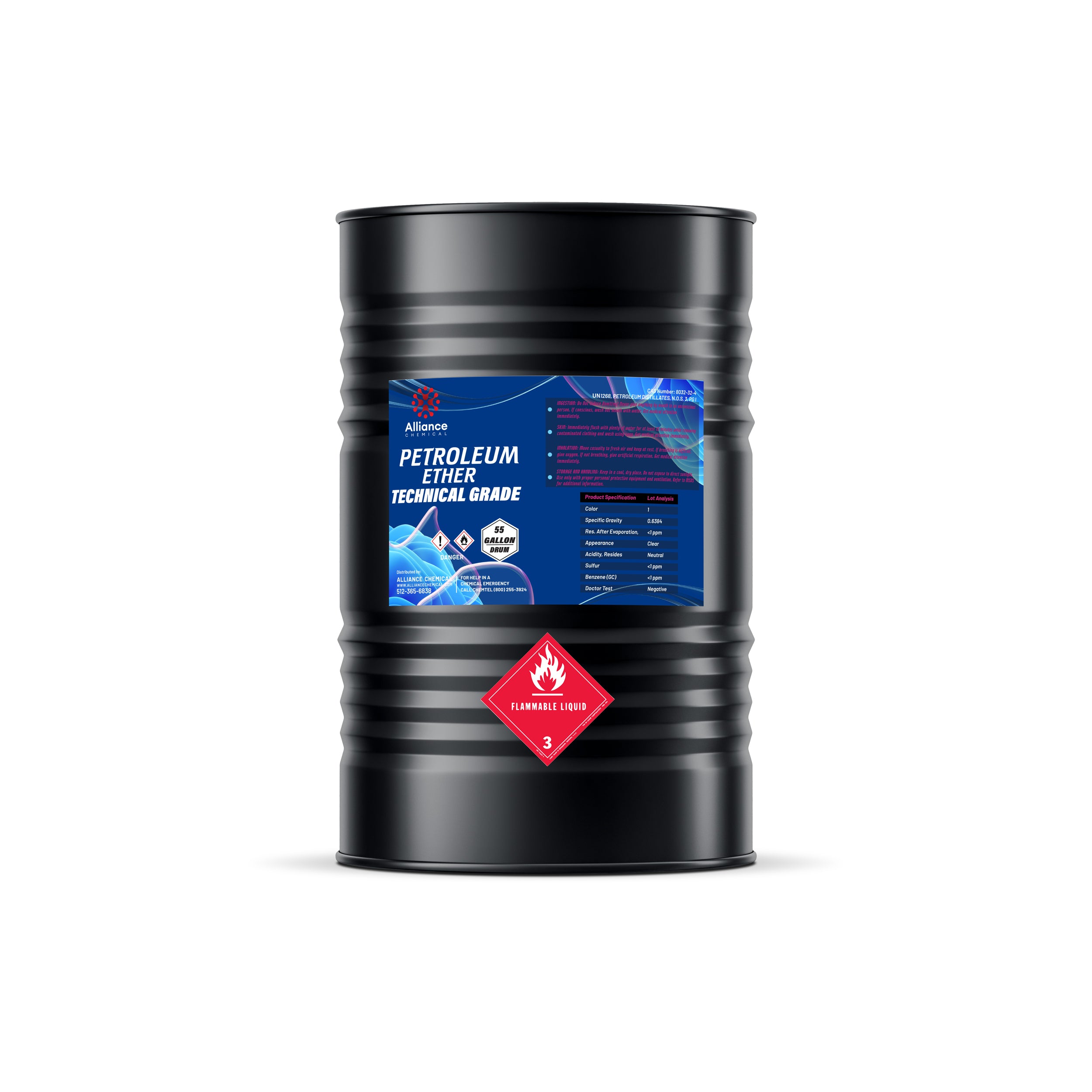

Petroleum Ether Technical Grade

Category : Solvents

$28.00

$190.00

85%

Off

Unit price

Quantity

Ask a question

Product Overview

Petroleum Ether Technical Grade is a refined aliphatic hydrocarbon solvent designed for applications requiring high volatility and low boiling points. The product is a clear, colorless liquid with a characteristic petroleum odor and a boiling range of 30–60°C, enabling rapid evaporation in drying and cleaning operations. Typical assay weight percentage for the hydrocarbon fraction falls in the 30–60% range, with a GC-determined value near 45%, ensuring consistent solvency across batch lots. Its low density (0.700 g/mL at 25°C) and a refractive index around 1.375 support compatibility with standard analytical and industrial processes, while a vapor pressure near 97 mmHg at 20°C indicates substantial volatility suitable for fast solvent turnover in manufacturing lines.

As a technical grade solvent, this petroleum ether is optimized for use where rapid drying and minimal residue are critical. It is formulated to minimize impurities that could affect analytical results or product performance, with tightly controlled trace levels of halides, metals, and sulfurous species in accordance with validated TDS specifications. The product is typically supplied with a low residue after ignition (<0.5%) and very low moisture content (<0.5%), delivered under inert conditions to preserve solvent integrity during storage and use. The composition and handling guidelines align with common industry standards for technical grade hydrocarbon solvents used in pharmaceutical, analytical, and manufacturing contexts.

Key Properties

- Property Name: Assay (Hydrocarbon Fraction)

- Chemical Formula: C₅H₁₂ (approx. mixture of low‑boiling aliphatic hydrocarbons)

- Molecular Weight: 86.0 g/mol

- Boiling Point (Range): 30–60°C

- Specific Gravity (20°C): 0.65–0.75 (typical 0.70)

- Color (APHA/Hazen): Max 10 (typical 5)

- Residue After Ignition: Max 0.5% (typical 0.2%)

- Chloride (Cl⁻): Max 2 ppm (typical 0.5 ppm)

- Nitrate (NO₃⁻): Max 5 ppm (typical 1 ppm)

- Ammonium (NH₄⁺): Max 5 ppm (typical 1 ppm)

- Sulfate (SO₄²⁻): Max 10 ppm (typical 2 ppm)

- Phosphate (PO₄³⁻): Max 5 ppm (typical 1 ppm)

- Arsenic (As): Max 0.1 ppm (typical 0.02 ppm)

- Heavy Metals (as Pb): Max 0.5 ppm (typical 0.1 ppm)

- Iron (Fe): Max 1 ppm (typical 0.2 ppm)

- Copper (Cu): Max 0.5 ppm (typical 0.1 ppm)

- Manganese (Mn): Max 0.5 ppm (typical 0.1 ppm)

- Water Content: Max 0.5% (typical 0.2%)

- Acidity (meq/100 g): Max 0.05 (typical 0.01)

- Purity Notes: Meets Technical Grade specification; fits use in pharmaceutical extraction and analytical labs

Common Applications

- Extraction Solvent: Detail-oriented extraction of active ingredients from plant materials in pharmaceutical formulations, with attention to selectivity and minimal carryover of impurities.

- Cleaning Agent: Industrial degreasing and equipment cleaning to remove oils and greases from metal surfaces and machinery.

- HPLC Mobile Phase: Used as a component in liquid chromatography mobile phases where rapid evaporation and low UV interferences are required.

- Solvent for Paints and Coatings: Formulation aid to adjust viscosity and enhance drying characteristics in coatings processing.

- Laboratory Solvent: General-purpose solvent for organic synthesis, chromatography, and sample preparation in research settings.

Safety Precautions

Handling and storage should follow standard flammable solvent practices. Store in a cool, dry place away from heat sources and open flames, using containers made of HDPE or glass. Ensure adequate ventilation during handling to minimize inhalation exposure, and keep containers tightly closed when not in use. Use appropriate PPE including chemical-resistant gloves and safety goggles to prevent skin and eye contact. Maintain separation from oxidizers and acids to minimize reactive hazards, and implement grounded transfer procedures to avoid static discharge.

Additional safety considerations include monitoring for exposure and emergency response readiness. The SDS indicates a DANGER signal word with Flam. Liq. 2 and Eye Irrit. 2 classifications. In case of exposure, follow standard first aid: for eyes, rinse with water for several minutes; for skin, wash with soap and water; for inhalation, move to fresh air; for ingestion, do not induce vomiting and seek medical attention. Have eyewash stations and appropriate fire suppression equipment (Class B fires) available in the work area. Transport of the material follows UN 3295 guidelines for petroleum distillates, n.o.s., Class 3, PG II.

Benefits

✔ High Volatility with Rapid Drying – Enables fast solvent evaporation and short cycle times in manufacturing and analytical workflows.

✔ Controlled Impurity Profile – Meets strict TDS limits for metals, halides, sulfur species, and moisture to preserve analytical accuracy and product quality.

| Property | Value |

|---|---|

| Formula | C5-C12 Hydrocarbons |

| Grade | Technical |

| Flash Point | -18 |

| Form | Liquid |

| Solubility | Soluble in organic solvents |

| Appearance | Clear, colorless liquid |

| Boiling Point | 30 °C |

| Specific Gravity | 0.64 |

| Industry | Industrial, Petroleum |

Compare Products

| Price |

|---|

| SKU |

| Rating |

| Discount |

| Vendor |

| Tags |

| Weight |

| Stock |

| Short Description |