Cadmium Oxide Powder Technical

Category : Inorganic Compounds

$70.00

Unit price

Quantity

Ask a question

Product Overview

Cadmium Oxide Powder Technical Grade (Cadmium(II) oxide, CdO) is a high-purity inorganic compound utilized extensively in industrial manufacturing. This yellow to red solid serves as a critical precursor for pigments, a semiconductor material, and a component in specialized ceramic applications. With a typical assay ranging from 99.0% to 100.5%, this material offers excellent thermal stability and specific electrical properties required for electronic components and high-performance coating systems.

Supplied as a free-flowing powder, Technical Grade Cadmium Oxide is insoluble in water but soluble in acids, allowing for controlled integration into chemical processes. It is widely used in the production of cadmium electrodes for storage batteries, ceramic glazes, and as a catalyst in organic reactions. This product is strictly intended for industrial and institutional use by qualified professionals.

Key Properties

- CAS Number: 1306-19-0

- Appearance: Yellow to red powder

- Chemical Formula: CdO

- Assay (CdO Content): 99.0 - 100.5 wt% (Typical 99.7%)

- Specific Gravity: ~8.2 g/mL at 20°C

- Solubility: Insoluble in water; soluble in acids and ammonium salts

- Residue After Ignition: Max 0.5%

- Molecular Weight: 192.23 g/mol

- Trace Impurities: Strictly controlled limits for Chloride, Nitrate, Sulfate, and metallic impurities (Pb, Fe, Cu) to ensure process reliability.

Common Applications

- Pigment Manufacturing: Primary precursor for cadmium pigments used in ceramics, enamels, and glass to achieve vibrant, heat-stable colors.

- Semiconductors & Electronics: utilized for its distinctive electrical properties in transparent conductive films and sensors.

- Battery Production: Essential component in the manufacturing of cadmium-based battery electrodes, offering high energy density.

- Electroplating: Used in cadmium plating baths to provide corrosion resistance to metals.

- Chemical Catalysis: Acts as a catalyst or support in hydrogenation and oxidation reactions.

Safety Precautions

WARNING: Cadmium compounds are toxic. This product must be handled with extreme care by trained personnel only.

- Engineering Controls: Use only in a chemical fume hood or well-ventilated area to prevent inhalation of dust or fumes.

- PPE: Wear NIOSH-approved respirators (N95 or higher), chemical-resistant gloves, and splash goggles.

- Storage: Keep container tightly closed in a cool, dry place. Store away from incompatibles such as magnesium.

- Disposal: Dispose of contents/container in accordance with local, regional, and federal regulations regarding hazardous waste.

Benefits

Industrial Purity – >99% Assay ensures consistent results in sensitive formulations.

Thermal Stability – Maintains integrity in high-temperature ceramic and glass processing.

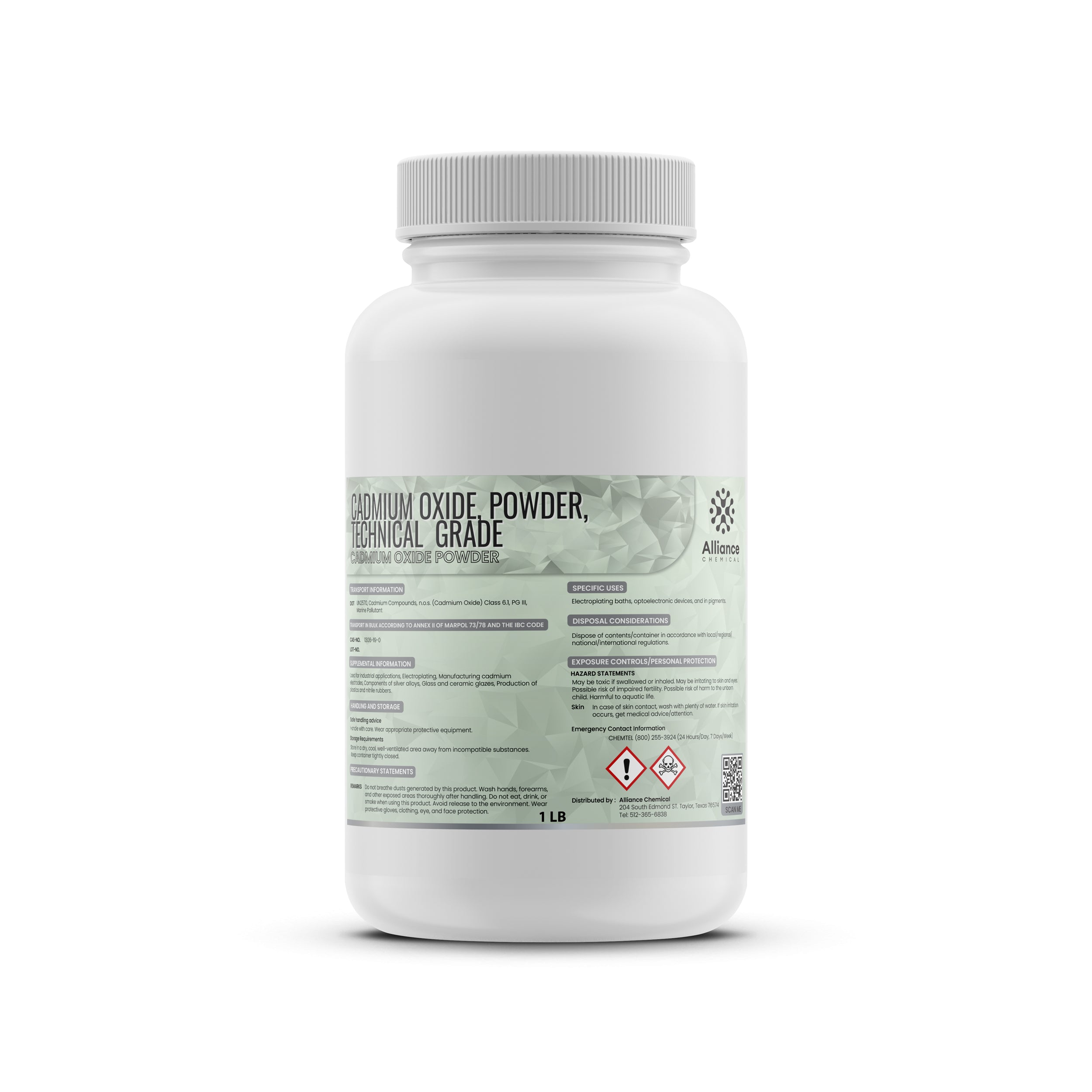

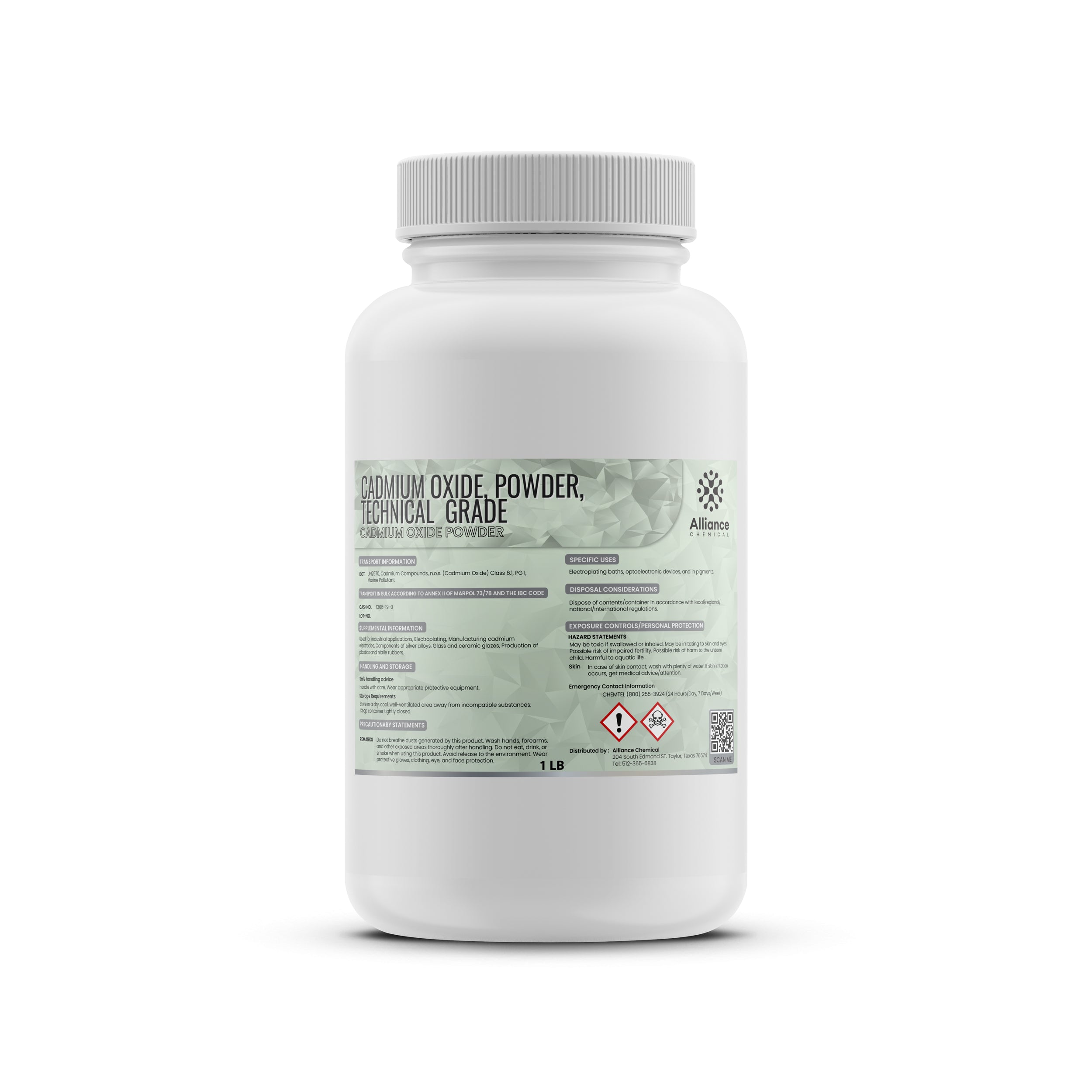

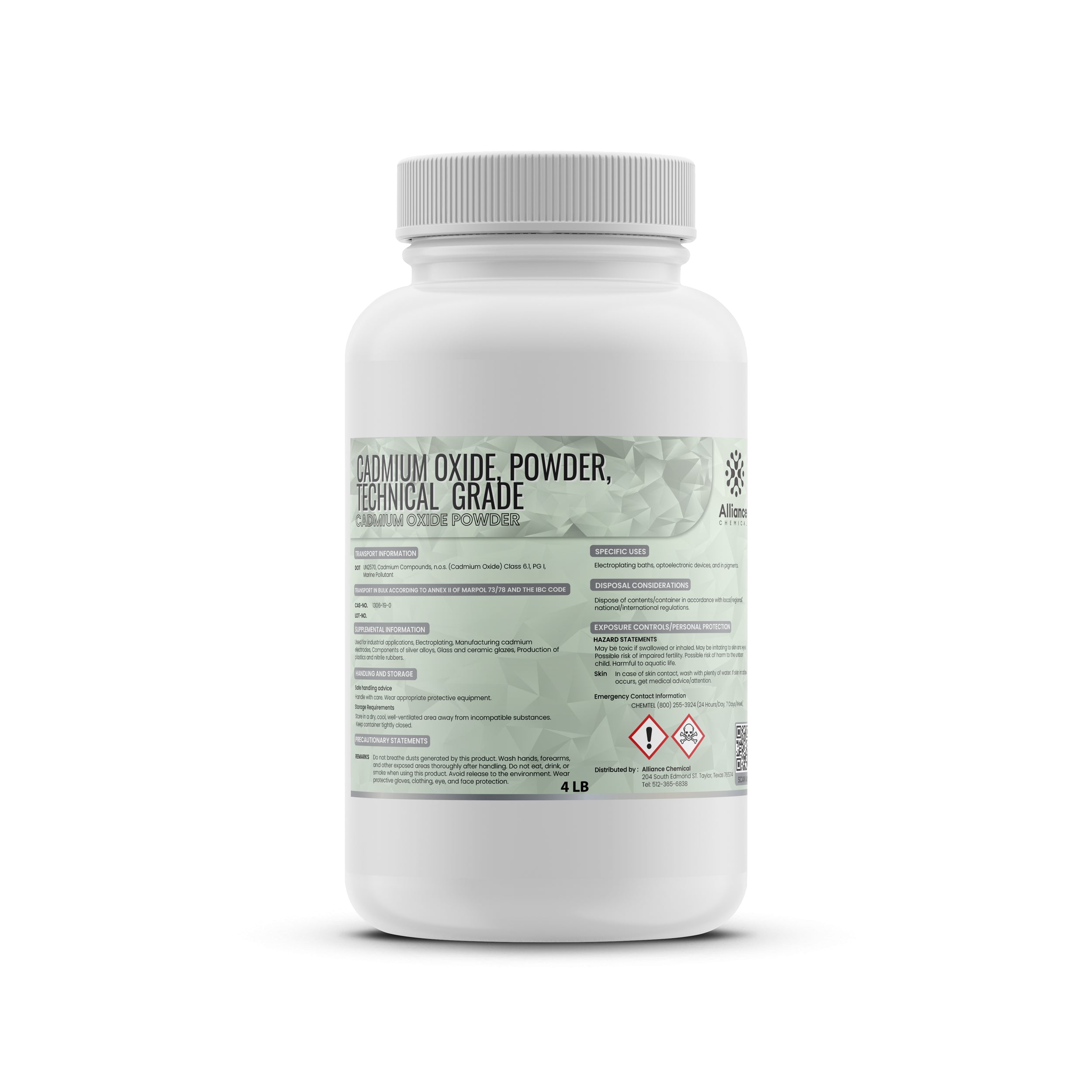

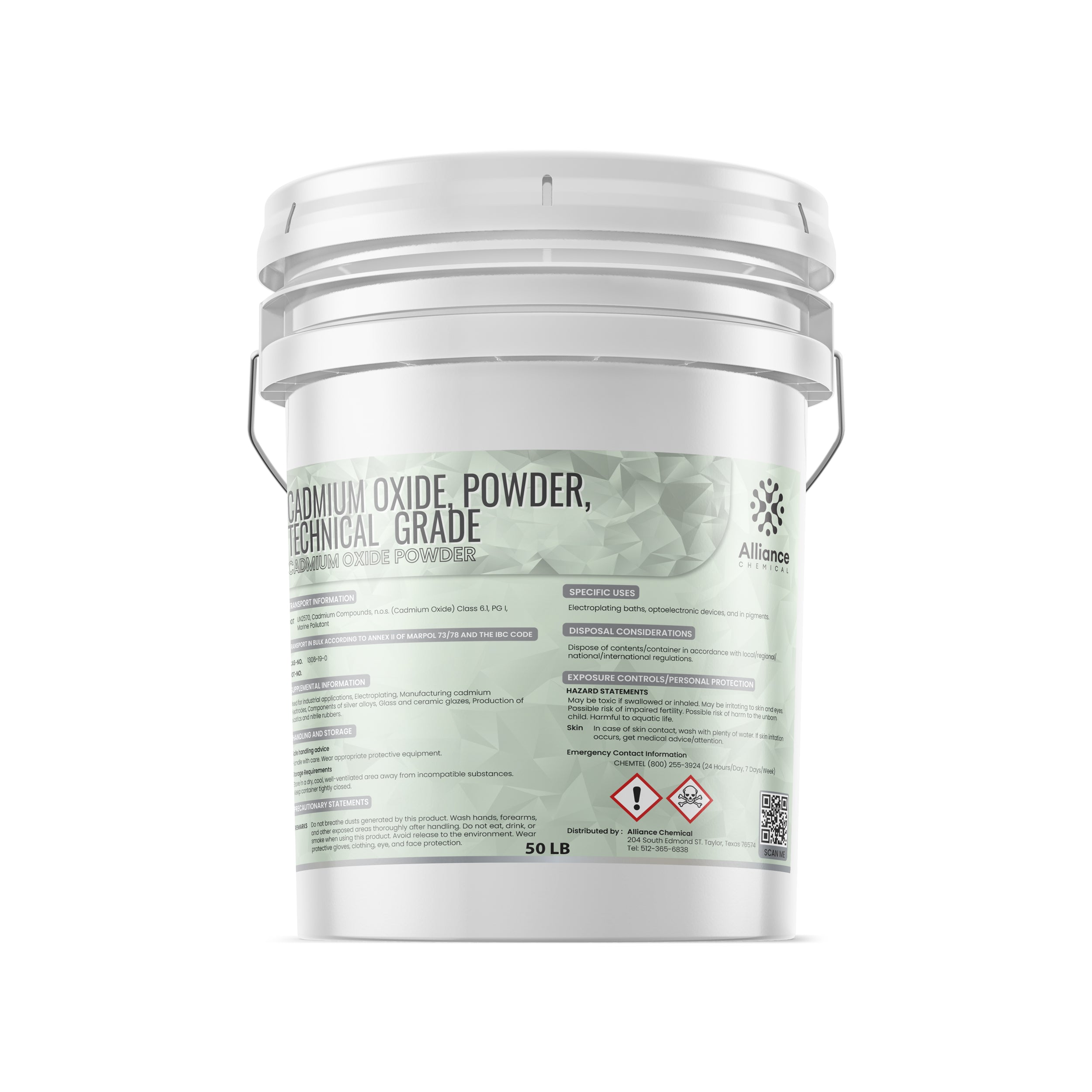

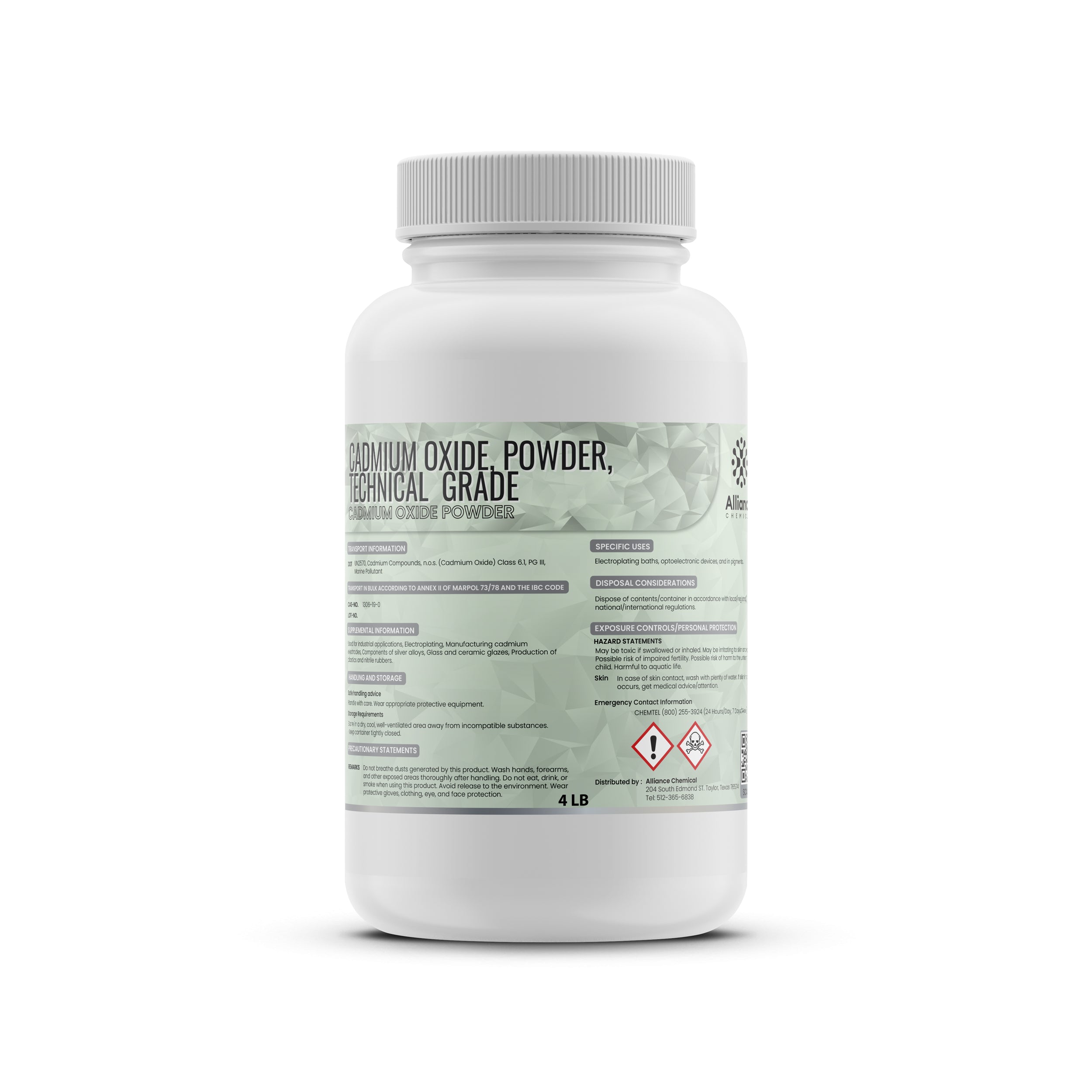

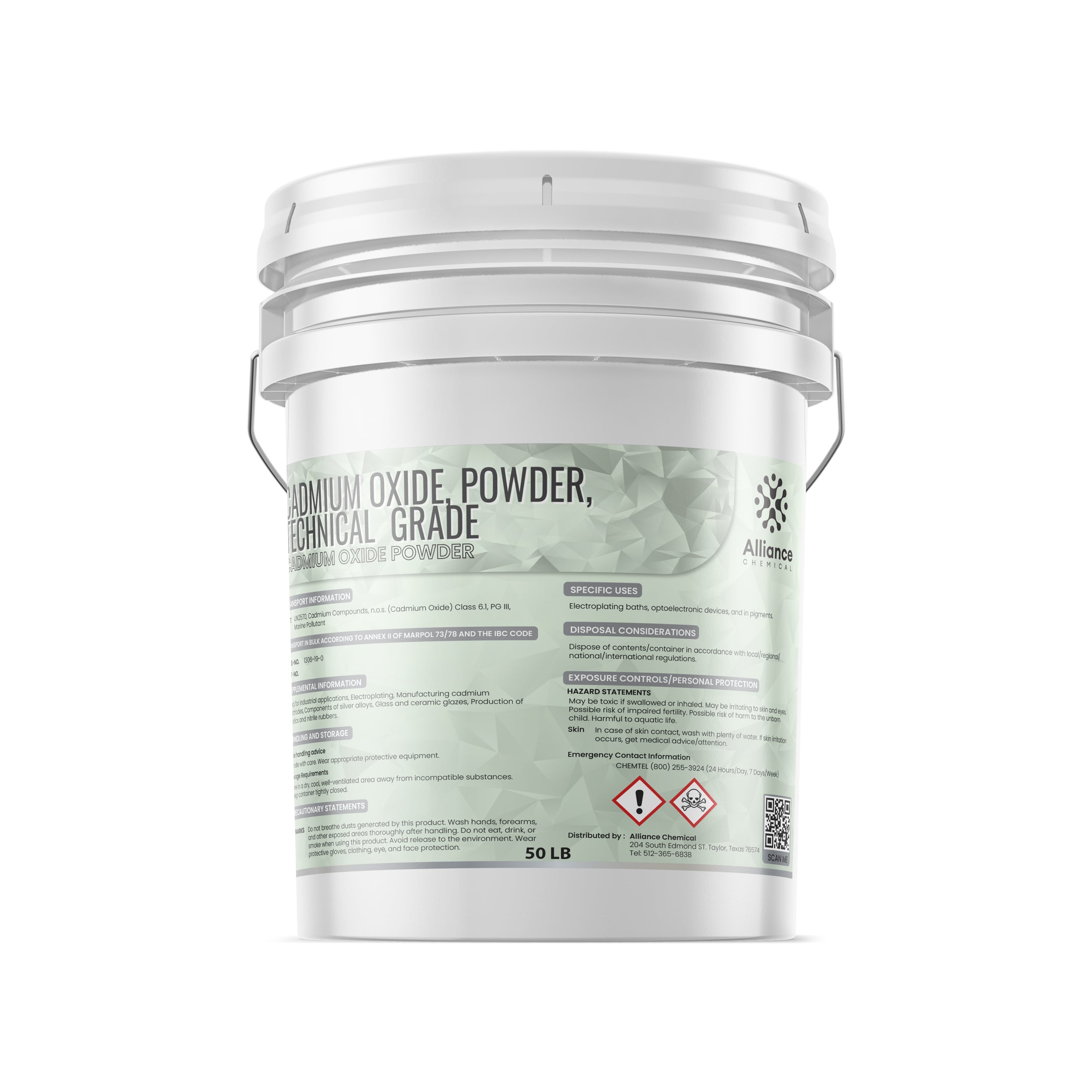

Versatile Packaging – Available in sizes ranging from 1 lb bottles to 50 lb bulk units.

Related Products

| Property | Value |

|---|---|

| Molecular Weight | 128.41 g/mol |

| Formula | CdO |

| Grade | Technical |

| Form | Solid |

| Solubility | Soluble in water |

| Appearance | Crystalline solid |

| Melting Point | 125 °C |

| Boiling Point | 240 °C |

| Specific Gravity | 1.5 |

| Industry | Industrial |

NYS-5K6-M9J

$70.00

Unit price

Compare Products

| Price |

|---|

| SKU |

| Rating |

| Discount |

| Vendor |

| Tags |

| Weight |

| Stock |

| Short Description |